|

In the forklift battery industry you have two choices either an old-school lead-acid battery or industry newbie Lithium Ion (Li Ion). Both have their own kinds of systems, setups, charging requirements, and price tags. While it looks like lead acids will be the industry leader through 2020 due to price and weight, within the next few years Lithium Ion will be as comparable in price and savings.

LEAD ACID BATTERIES

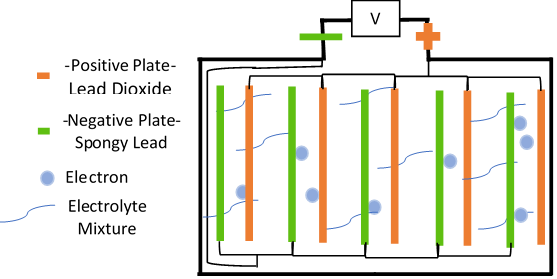

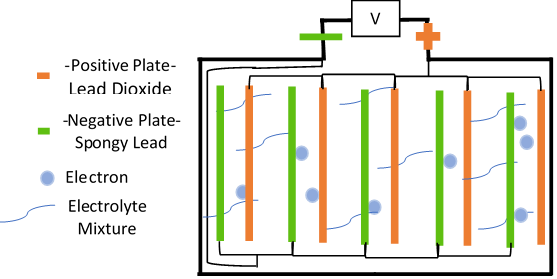

Lead acid forklift batteries have two main functions. They provide a power source and act as a counterweight to a lift truck. A typical lead acid battery is made up of a battery case, battery cells, and battery cables that come together to house a liquid electrolyte mixture of sulfuric acid and water.

How Lead Acid Batteries Work

Every battery cell houses layers of lead dioxide and spongy lead in alternating plates. When the charged acidic electrolyte mixture comes into contact with the plates; it creates an imbalance of electrons between the plates. Electrons will naturally travel from the negative spongy plate to the positive lead dioxide plate, attempting to correct the imbalance. This addition of electrons changes the lead dioxide in the positive plate into lead sulfate; this reaction is what creates the electrical charge that flows through the terminals and into your lift. This process is called discharging.

LITHIUM ION BATTERIES:

How Lithium Ion Batteries Work

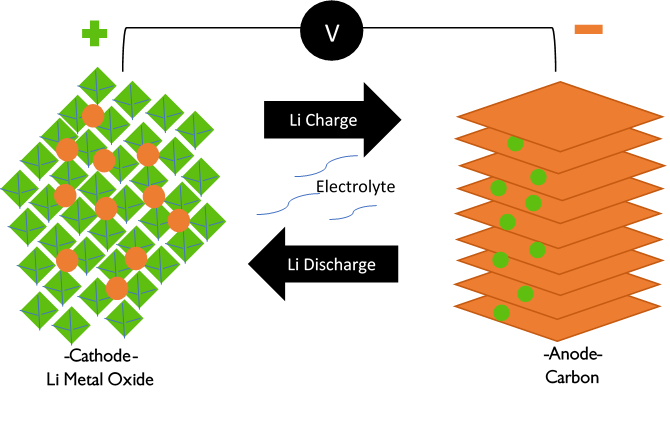

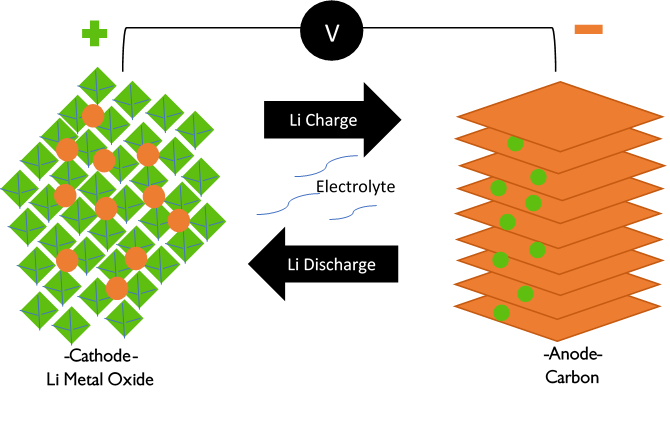

Lithium Ion batteries are made up of an anode, cathode, separator, electrolyte, and positive and negative terminals. The anode and cathode house the lithium. The electrolyte carries positively charged lithium ions from the anode to the cathode and then back again through the separator. The movement of the lithium ions creates free electrons in the anode which creates a charge at the positive terminal. The electrical current then flows from the positive terminal through the lift to the negative terminal. The separator blocks the flow of electrons inside the battery.

When the battery is discharging and it provides an electric current, the anode releases lithium ions to the cathode, creating a flow of electrons from one side to the other. When plugging in the battery to charge, the exact opposite happens: Lithium ions are released by the cathode and received by the anode charging the battery.

Advantages:

★ Long cycle and extend shelf-life

★ Maintenance Free

★ High energy capacity

★ Short charge times

★ Low self-discharge

★ Worker and Environmental Safety, no hydrogen fumes or acid splash hazards

★ Less time and labor expended by workers swapping out lead acid batteries or maintain them

After three to four years of use, lead-acid industrial forklift batteries start to pronouncedly lose their ability to hold a charge. The result is less productive time in-between charges. If you continue to use it after this time the forklift battery’s capacity will be reduced at an ever-accelerating rate until finally the batteries are of no functional use and need to be replaced.

But here at Wisdom Power Forklift Batteries, we can extend the functional life of your industrial forklift batteries. More than 10 years of accumulated experience have allowed us to develop a unique, non-invasive 18 step forklift battery reconditioning process which includes diagnosis, neutralization, desulphation, cleaning, and an anti-corrosive paint treatment.

By reconditioning industrial forklift batteries utilizing our forklift battery reconditioning techniques, we can help avoid the unnecessary smelting of industrial lead-acid forklift batteries which helps to decrease environmental pollution and CO2 emissions. By extending the life span of your lead-acid industrial forklift batteries the amount of replacement battery purchases will be reduced, which helps your company save money in the long-term. All reconditioned forklift batteries are delivered with full warranty.

This can almost double the lifespan of a battery, as it allows you to get further use out of the same battery. This is preferable to using a failing battery, which allows for fewer productive hours, or a second battery throughout the day.

Need to dispose of your scrap forklift batteries?

We will pay more for your scrap forklift batteries than they are worth in scrap! This is a great way to make a little bit of extra money while also helping us provide others with affordable alternative power sources for forklifts. Learn more here!

We have the experience and know-how needed for storage, handling, and shipping of lead-acid forklift batteries.

With two great choices you can see how many battery debates start. It all comes down to you, your application, and your preference between old and new technology. With new strides in the battery industry either choice could be right for you. Call or e-mail us to learn more about what we have to offer.

|