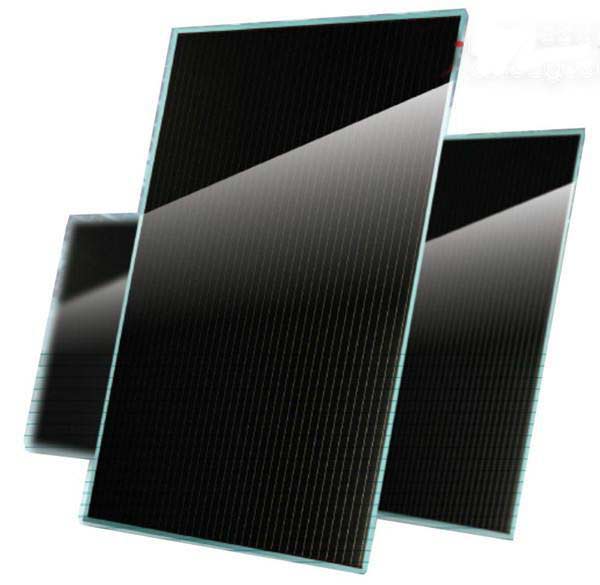

Classification of solar cell panels

1, polycrystalline silicon solar cells

Both single-crystal silicon cells, high conversion efficiency and long life and amorphous silicon thin-film battery material preparation process is relatively simple and other advantages of a new generation of batteries, the conversion efficiency is generally about 12%, slightly lower than monocrystalline silicon solar cells, There is no significant efficiency degradation problems, and may be prepared inexpensive substrate materials, the cost is far lower than the cost of single-crystal silicon cells, and higher efficiency than amorphous silicon thin-film batteries.

2, monocrystalline silicon solar cells

High-purity monocrystalline silicon rod as raw material for solar cells, is currently the fastest development of a solar cell. Its structure and production process has been finalized, the product has been widely used in space and the ground. Monocrystalline silicon solar cell photoelectric conversion efficiency of 15%, laboratory results have more than 20%. low cost.

3, amorphous silicon solar cells

Amorphous silicon solar cell manufacturing temperature is very low (~ 200 ℃), easy to realize the advantages of large area, so that the thin film solar cells occupy the first position in the manufacturing methods of electronic cyclotron resonance, photochemical vapor deposition, DC Glow discharge method, radio frequency glow discharge method, splashing method and hot filament method. In particular, the RF glow discharge method is an internationally recognized mature technology because of its low temperature process (~ 200 ℃), easy to achieve large area and large quantities of continuous production.